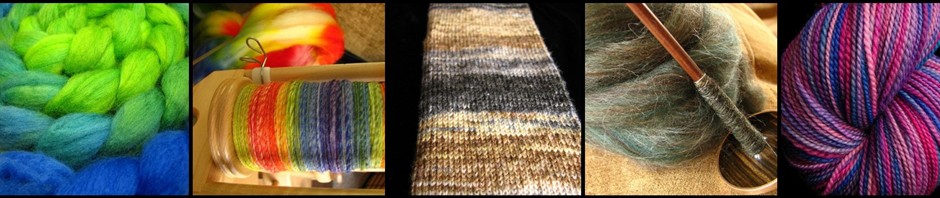

A couple of weeks ago, I felt the need for a quick project, so I pulled out some skeins of Tiger Cub I set back for myself, and worked toward making a ‘thing’.

These skeins are kettle dyed, which means fairly random. I didn’t want to fight with the patterning, so decided a simple plain weave would be fine. Plain weave is your basic alternating of threads, over and under. Next came deciding how close I should put each thread….my loom has a 10 dents per inch reed, but measuring the wraps per inch of the yarn suggested I might like 12 ends per inch. Since I wanted to make a large scarf/small shawl (hence ‘Sharf’) with some drape, I decided to go the easy route and go with 10 epi. Then came some serious calculation of how wide and long I could make it with the yarn I had. I decided I could make it 16 inches in the reed, expecting it to shrink in width. I measured out 3 yards (108″) of warp, using all of one skein, and some of the other to get 160 ends. I tried warping back to front, using the built in raddle…..this was a disaster….again. This time, the fuzzy yarn would catch together and get stuck in the raddle. I guess I’ll be a front to back girl!

Here it is in progress. One goal of this sharf is to continue to get better at selvedges (I’ve discovered that for me, on this loom (a Louet Kombo), my selvedges are better if I beat with the shed open, then change the shed before I let the beater go. Another note….as this was patterned yarn, I didn’t want the pattern to change every time my bobbin did (yes, there is pattern even within random!). So I took an extra step with my bobbins, winding one, then re-winding it so the yarn was always going in the direction it came off the skein.

Another goal is to learn to pay attention to how hard I’m beating in the weft, trying to get 10 picks per every inch and 3/8ths, to give me an even and square cloth when finished. I measured how much the yarn stretches under tension to get an idea of how long I needed to stretch my picks over…..if I had gone with 10 per inch, my fabric would be a little weft faced when finished, and I would have run out of yarn before the length I wanted. See how open the above picture is. It looks too open, doesn’t it?

Everything went great until the last 18 inches or so, then the effects of the disastrous warping became very obvious, and the shed was lousy. No problem, though. I did some needle weaving while this was still on the loom and corrected the mistakes. Just weave a new piece of yarn several inches before and after the mistake, then cut the mistake yarn out, leaving overlap.

Lookit, better selvedges! And the sett looks better now that it is off the loom, although it is still really floppy, or that fun weaving term: ‘sleazy’.

And, rather longer than I expected. It was 78 x 15″ off the loom, fringe not included. And this is where I stalled. I haven’t purchased a fringe twister yet, so I’m doing this by hand. Well, sort of. I set up my bobbin winder, measured 6 inches on my fringe, then used a clothespin to attach two strands to the bobbin winder….2 turns. Hold those two, add two turns to the next pair, then knot those two sets together and allow the twist to settle. It worked pretty well, if fiddly.

And then came the time of reckoning….time to wash. Since this yarn is superwash, I used my machine set on delicate, cold water, and some Ecos detergent (which is pH neutral and safe for hand dyed wool). Then I tumbled it in the dryer for a bit. It fluffed out marvelously, so 10 epi was the right call. I did have some of the fringe pull…so I’ll consider that for my next project. The sharf is now more scarf like, at 75 x 14″.

I wore it to church this Sunday. Yay!

Beautiful – congratulations! I love all the pictures, especially the close-ups; I’m not a weaver so it’s fun to see what it looks like along the way.